Laboratory batch flotation test work is a mainstay in a metallurgist’s toolkit. Whether for ore characterisation or optimisation studies, determination (and comparison) of recoveries are typically the key objective.

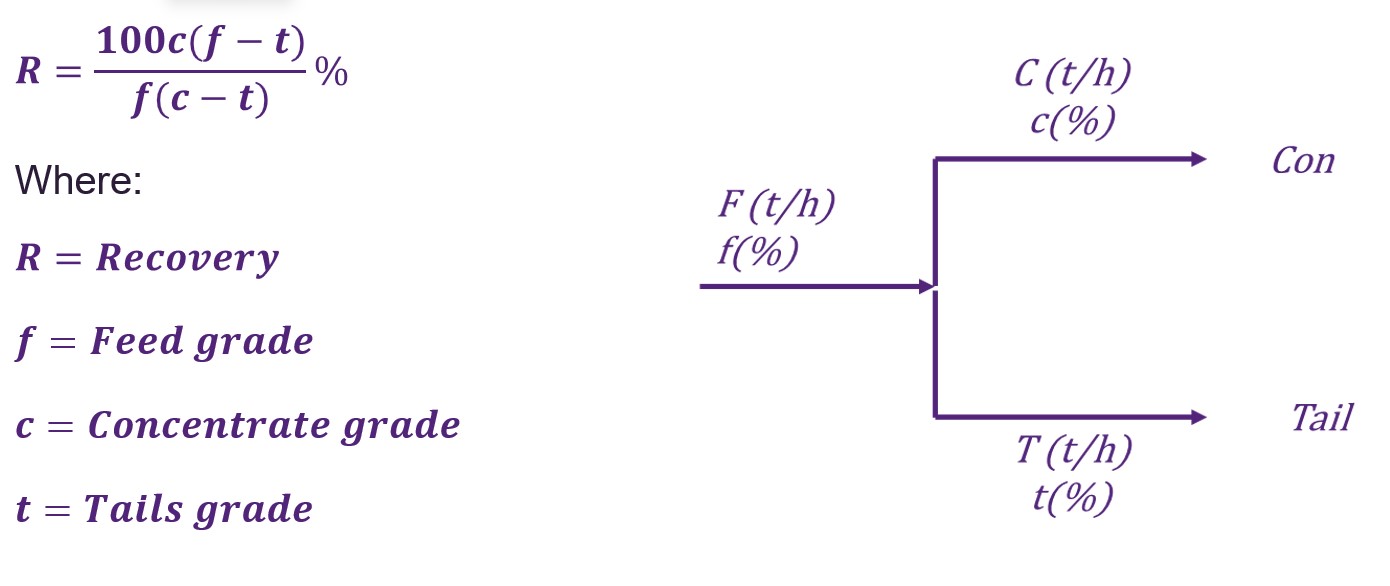

When calculating recovery, many metallurgists rely upon the ‘2-product formula’:

Though a simple and useful formula, datasets with experimental inconsistencies (where mass IN ¹ mass OUT) will result in errors in calculated recoveries.

A simple mass balance using the minimisation of the sum of squared errors can create a self-consistent data set. This can be undertaken quite quickly in Excel using the Solver add-in, even when balancing multiple elements.

Unfortunately, even the most carefully collected sample will have associated errors and uncertainties, and these will propagate through subsequent calculations. This can be quantified using the 2-product formula error propagation calculator in JKToolKit. We also know that not all measurements are equal; some are better than others. We do not want ‘noisy’ measurements to drive the mass balance as much as those that are considered to be reliable. Therefore, an ‘error weighting’ should be incorporated in the mass balance methodology.

Again, this can also be undertaken in Excel using the Solver add-in. However, for those who prefer a graphical flowsheet and/or who must manage the complexities of multiple nodes with recycle streams, dedicated software such as JKSimMet or JKSimFloat can be used to streamline the analysis.

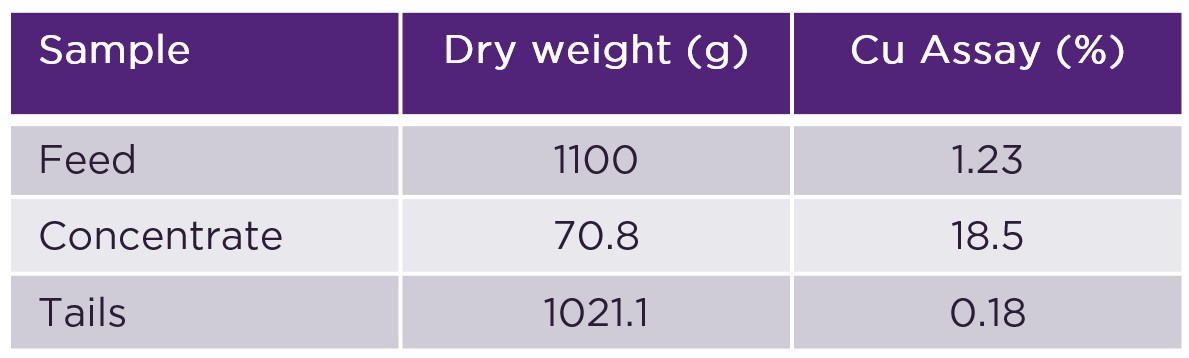

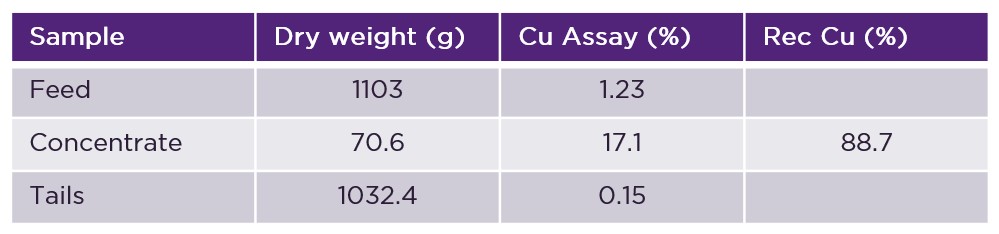

To illustrate, consider the following batch flotation example:

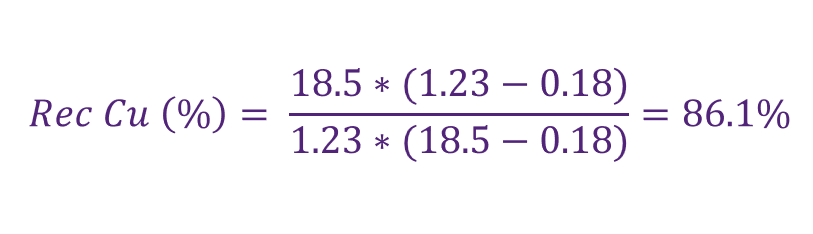

Cu recovery calculated using the 2-product formula yields the following value (86.1%):

On the other hand, mass balancing using appropriate standard deviations(*)for each data point generates a self-consistent data set, ensuring that mass is conserved across the feed and product streams. The resulting recovery, adjusted to 88.7%, is shown below.

(*) The mass balance performed assuming a high level of confidence in the feed and concentrate dry weight and feed assay measurements.

As economic decisions are often made from laboratory batch flotation test work, it is critical that the values we calculate best represent the system we are investigating.

JKTech offers a range of flotation testing options, from optimising existing circuits to flowsheet development for greenfield projects. Learn more about our services by visiting our Flotation Testing page.