Consulting

JKTech integrates geometallurgy, blasting, mining, comminution, mineral separation, mine waste characterisation and waste disposal to ensure sustainable improvements in project value.

Mine-to-MillTM is a methodology developed by JKMRC to provide the mining industry with major benefits across the blasting and comminution processes. JKTech has expanded this to integrate disciplines across the value chain and tailored it to our clients’ requirements, which range from scoping studies to operations. This methodology is called: JK Value Chain Optimisation.

This methodology identifies opportunities and risks, providing operating strategies to ensure the improvements are sustained, starting with the resource through to the final product.

Geometallurgy

JKTech's geometallurgy services range from understanding the rock through to identifying products that will enhance opportunities and reduce risks, enable sustainable process optimisation, and improve forecasting at a tactical and/or strategic level.

Our approach includes the characterisation and classification of material types, modelling the spatial variability of material types, followed by predicting expected performance under constrained conditions. We believe geometallurgy extends beyond traditional metallurgical processes such as comminution, flotation, separation by density, and leaching, to include other key extraction processes such as blasting, acid mine drainage, dewatering, dust and material handling.

JKTech geometallurgical expertise includes:

Geometallurgical consulting

JKTech assists clients to undertake part or the whole of the journey to delivering value. This includes the identification of key processing issues, design and analysis of geometallurgical characterisation programs, identification of key geological drivers of performance, classification and domaining, proxy-based data analysis and models, spatial modelling, performance models, forecasting, scenario modelling and technical risk assessments.

Geometallurgical characterisation

JKTech offers a suite of geometallurgical tests for the small mass, high volume characterisation of processing attributes to compliment traditional metallurgical tests. Characterisation can include XRD, process mineralogy, crushing, grinding and abrasion tests; rougher and cleaner flotation tests; and static and kinetic acid rock drainage tests.

Mine Waste Characterisation

Mine Waste Transformation through Characterisation (MIWATCH)

The methodology utilises a systematic sampling and analysis protocol for tailings and waste rock characterisation, developed and implemented by the MIWATCH Research Group, founded in 2021, at The University of Queensland's Sustainable Minerals Institute.

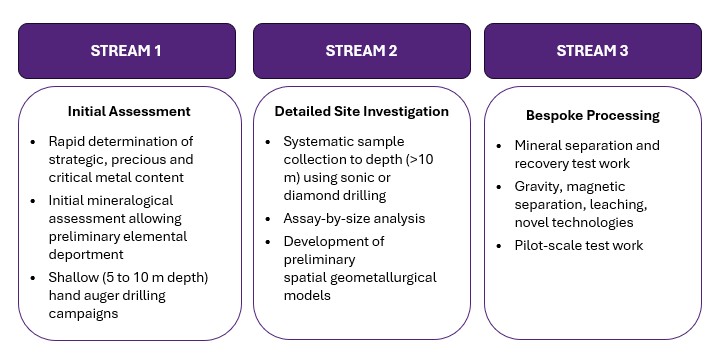

MIWATCH has developed three working programs for mine waste characterisation, which are now being offered to the industry by JKTech.

MIWATCH Stream Programs

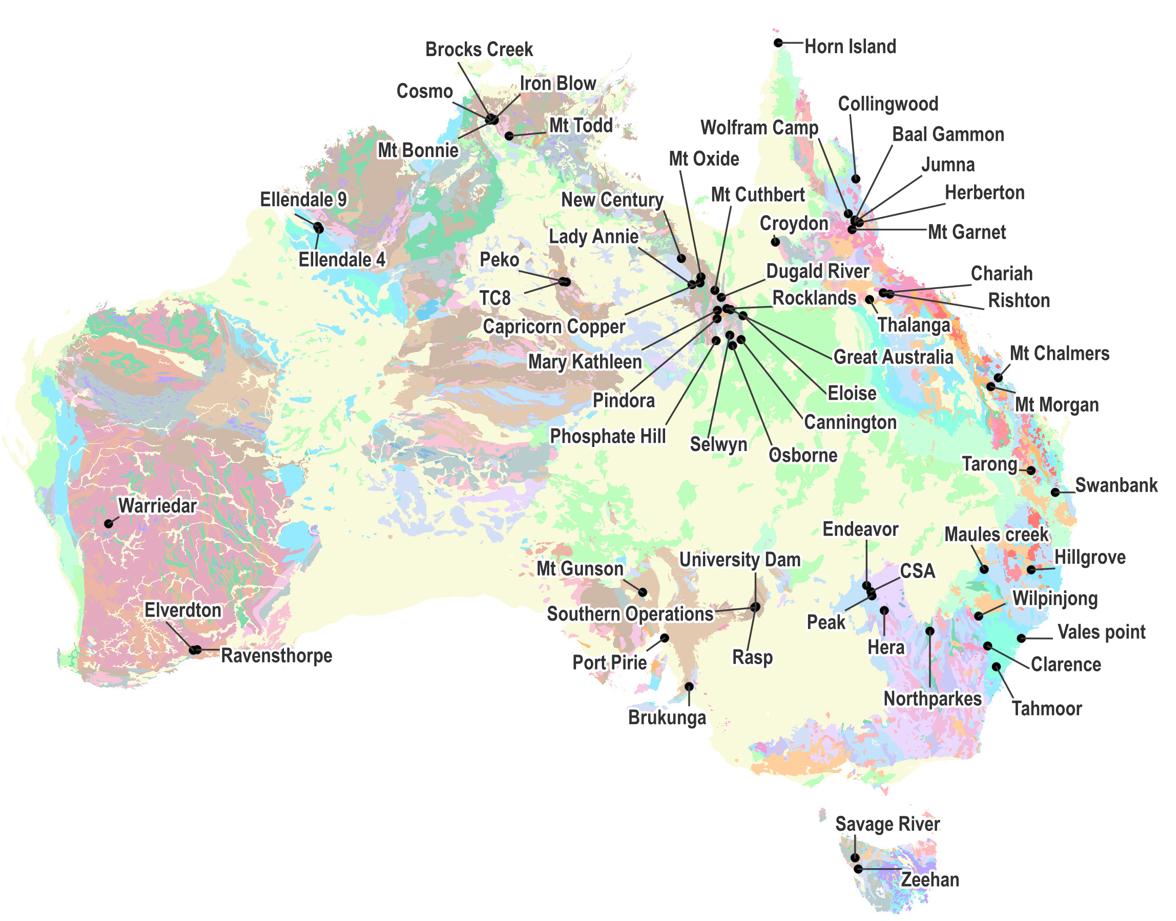

MIWATCH have delivered over 80 Stream 1 programs across Australia with Stream 2 programs being delivered both nationally and internationally, including characterisation of the historic Mt Isa tailings as part of Glencore's tailings reprocessing project (Stefoni et al., 2025). Stream 3 programs have been delivered in collaboration with various partners to select the most compatible reprocessing technologies based on intrinsic tailings properties.

Mining

Our team of world class mining professionals provide you with holistic solutions to improve the overall performance of your mining operation.

Dilution and ore loss management

The management of ore loss and dilution is an important aspect of productivity and efficiency, particularly in structured orebodies. JKTech uses its newly-released JK Value Based Ore Control (JKVBOC) tool to measure and model blast-induced movement and develop strategies to minimise ore loss and dilution.

Open cast blast optimisation

Open cast blast optimisation solutions also make use of the JKVBOC and other tools developed by JKMRC/BRC to understand the effect of blasting on coal loss and coal fines, to then optimise blast design and increase overall profitability. This methodology has been successfully applied at several large open cast coal mines and has significantly improved coal recoveries.

Blast audits and optimisation

Blast audits assess the quality of blast design and implementation and provide an insight into problems in blast fragmentation, diggability and damage. The audit results, in conjunction with JKTech domain knowledge and tools, provide practical solutions to improve the blasting process.

Mining productivity analytics

Data analytics are a key component of drill and blast improvement through the integration of geological, blast design, fragmentation and load and haul data. Photographic techniques enable the analysis of fragmentation distribution resulting from blasts while high speed filming provides valuable quantitative information about how rock structure, firing sequence, burden movement and explosives energy interact to affect fragmentation and muckpile information. Analysis of such data provides insights, knowledge and direct feedback to operations enabling consistent high performance.

Mining-related products and services

JKTech offers professional development across topics such as drill and blast QA/QC, blast design, blast optimisation.

Processing

Comminution

Our methodology has been proven to effectively design comminution circuits and optimise plant performance via the improved productivity and efficiency of comminution and classification circuits around the world.

Our comminution consultants combine years of experience in plant operating practices with a detailed knowledge of the specialist JKTech modelling software which is supported by a very large database of operating sites. Over the years, our consultants have been involved in design and optimisation studies in hundreds of different mineral processing plants around the world. The comminution consulting team are highly skilled specialists with expertise in:

- Design and optimisation of comminution circuits

- Comminution modelling and simulation

- Comminution process training

- Comminution process benchmarking

Comminution-related products and services

- We are the developers JKSimMet, an award-winning software package for the analysis and simulation of comminution and classification circuits in mineral processing operations.

- We offer professional development in ‘Simulation and Optimisation of Crushing and Grinding Circuits’.

- Our laboratory offers a suite of tests providing ore characterisation data that can be used in comminution circuit design and simulations as well as to compare the breakage characteristics of past, current and future ore types.

- Our range of specialist comminution test equipment enables JK Drop Weight and SMC tests to be conducted which are industry-standard tests for ore hardness.

Mineral separation

Using our operational experience together with our unique evaluation and optimisation methodology, JKTech has improved the operability and performance of mineral separation circuits across a wide range of commodities. Our team is the best equipped to meet all your needs.

Mineral separation-related products and services

- We use our expert knowledge in mineral separation and mineralogy to improve mineral separation plant performance, recommend upgrades, and design flowsheets using JKSimFloat.

- We offer professional development in ‘Measurement, Modelling and Simulation of Flotation Circuits’.

- Our laboratory offers batch flotation testing to specified test conditions, for optimisation of flotation conditions through to reagent trials and design projects.

- Our range of specialist flotation test equipment is the result of decades of flotation characterisation research and development by the JKMRC and industry.

Mineralogical assessment

Mineralogical analysis can be a powerful tool to provide insights across the value chain and lifecycle of mining projects and operations through routine plant monitoring and future ore characterisation.

We apply mineralogical assessment in the following applications;

- waste and ore characterisation;

- material and ore typing;

- estimating primary grind and regrind targets;

- developing conceptual flowsheets for mineral separation;

- routine plant monitoring for process improvement;

- precious metal and penalty element deportment;

- implications for rheology and dewatering;

- assisting in tailings design and management.

JKTech uses a number of mineralogical techniques depending on the objectives and cost vs. benefit including optical, hyperspectral imaging, XRD, MLA, QEMSCAN and microprobe.