A strategic goal for any operation is to minimise recovery losses while maintaining concentrate grade targets.

The strategies to achieve this, however, come in many shapes and forms. Some examples include:

- Better process control to help maintain circuit stability by reducing the impact of disturbances.

- Understanding mineralogical properties to appropriately define the grind size of the flotation feed, reagent suite, pH targets, and processing strategies for achieving best metallurgical performance.

When it comes to determining the balance between throughput vs. recovery, mathematical modelling has long been demonstrated to be a powerful tool in quantifying this balance and how it is affected by feed kinetics and circuit flowsheet configuration.

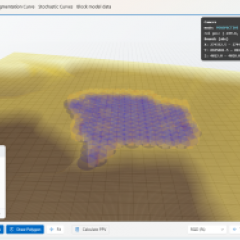

JKSimFloat is widely regarded as the industry benchmark flotation modelling and simulation package. It streamlines tasks related to the mass balancing, modelling and simulation of flotation plants, making it easier for users to identify process bottlenecks and assess requirements for future throughput expansions. The software is used by major flotation equipment vendors in their assessments for flotation equipment design and upgrades.

The Floatability Component Model (FCM), developed as part of the AMIRA P9 research project at the JKMRC, underpins the predictive capabilities of JKSimFloat. This model accounts for the kinetic response of different minerals in a flotation system, which is driven by both the characteristics of the ore, and the environment where flotation occurs. The parameters for the model are derived from flotation plant survey data. Managing and making sense of these large datasets is key to JKSimFloat’s role in flotation process improvement.

After calibration and validation of a model against plant performance, simulation can be performed in the JKSimFloat environment to identify strategies that improve flotation performance by testing different ‘what-if’ scenarios. For example:

- How would the cleaner circuit cope if mass pull in the rougher circuit is increased?

- If a new ore type is expected, are there any negative impacts on flotation performance?

- What is the effect of changing stream destinations on circuit performance? What flowsheet configurations should be considered and tested?

Simulation allows these changes to be assessed and de-risked, prior to implementation in the field.

Recent upgrades to JKSimFloat’s model-fitting functionalities streamline the model-development process, circumventing the time-consuming approach of undertaking this step in spreadsheets.

Case study: Evaluating flowsheet options with simulation methods

Background

A recent JKTech client (one of the largest global produces of Pb) had a flotation plant comprised of numerous banks of OK8 and OK3 cells. Continued growth created a need for expansions to increase plant capacity.

Approach

A JKSimFloat model was developed to predict changes in flotation response with expected variations in feed throughput, bank residence time, circuit stream destinations, and in-kind replacement of flotation cells within the Pb cleaner circuit.

Scope of Work

- Mass balancing flotation survey data to generate a reconciled-dataset for the calibration of a JKSimFloat model;

- Calibration of a site-specific flotation model in JKSimFloat;

- Predicting flotation response under the following scenarios:

- Increased plant throughput (+5, +10 and +15%);

- Increasing capacity of the Pb cleaner circuit via additional OK8 and OK3 cells;

- In-kind replacements of the OK cells in the Pb cleaner circuit

Results

The JKSimFloat predictions indicated that:

- Increasing throughput (up to +15%) would be detrimental to Pb and Zn recoveries (up to 3% losses) due to the reduction in circuit residence time. However, the model predicted that these losses could be mitigated with additional capacity in the rougher and cleaner circuits to provide additional residence time for slow-floating minerals.

- Replacing the OK3 cells in the lead (Pb) cleaner cells with equivalent units would improve gas dispersion within these cells. This enhancement was predicted to improve lead recovery by ~2-3%, but with a ~1-2% reduction in Pb concentrate grade.

The model further predicted an increase of ~4-5% in Pb recovery at similar or better Pb concentrate grades with additional cleaning capacity using the in-kind OK3 cells. The predictions also showed that increasing recovery in the Pb circuit would inadvertently increase the amount of Zn misreporting to the Pb concentrate. This highlighted the need for management of Zn activation in the Pb circuit through mineralogical studies and careful reagent selection.

Benefits of JKSimFloat

- Reducing the need for a 'trial-and-error' approach to circuit improvement by identifying the most promising strategies prior to testing in the plant;

- Streamlining the management and analysis of large and complex survey datasets required for the calibration of the flotation models to production-scale flotation circuits.

For more information about JKSimFloat Software, training or flotation optimisation and modelling capabilities please contact us.