This is a summary of collaborative work undertaken by Ban Houayxai and JKTech personnel to improve throughput. The work is a summary of papers presented at The Orebody Modelling and Strategic Mine Planning Symposium 2014 and the 11th International Symposium on Rock Fragmentation by Blasting 2015.

Ban Houayxai Gold Mine

The Ban Houayxai Gold Mine (BHX) is located in Laos and operated by Phu Bia Mining, a 90% owned subsidiary of Pan Aust. The Laos government owns the remaining 10%.

The Ban Houayxai Gold Mine (BHX) is located in Laos and operated by Phu Bia Mining, a 90% owned subsidiary of Pan Aust. The Laos government owns the remaining 10%.

The mine is an open pit operation with a semi-autogenous grinding/ball (SAB) and carbon-in-leach (CIL) processing circuit.

Production commenced in 2012 and is approximately 100,000 oz of gold and 600,000 oz of silver per annum.

Gold and silver mineralisation occurs as structurally-controlled narrow veins and disseminations and within a volcano-sedimentary sequence. Quartz- pyrite± carbonate± electrum± native silver veins are the most commonly mineralised. Disseminated mineralisation is predominately associated with silicification of the feldspathic sandstone with higher grades in breccias.

At the end of 2013, the Mineral Resource at BHX stood at 64 Mt at 0.90 g/t Au and 7.1 g/t Ag for a total of 1.8 Moz Au with Ore Reserves of 36 Mt at 0.81 g/t Au and 8.0 g/t Ag.

Context

The first two years of operation had processed predominately soft oxidized ore but significant variation in milling rates was being seen due to variability in the feed properties of the oxide, transitional and primary ores.

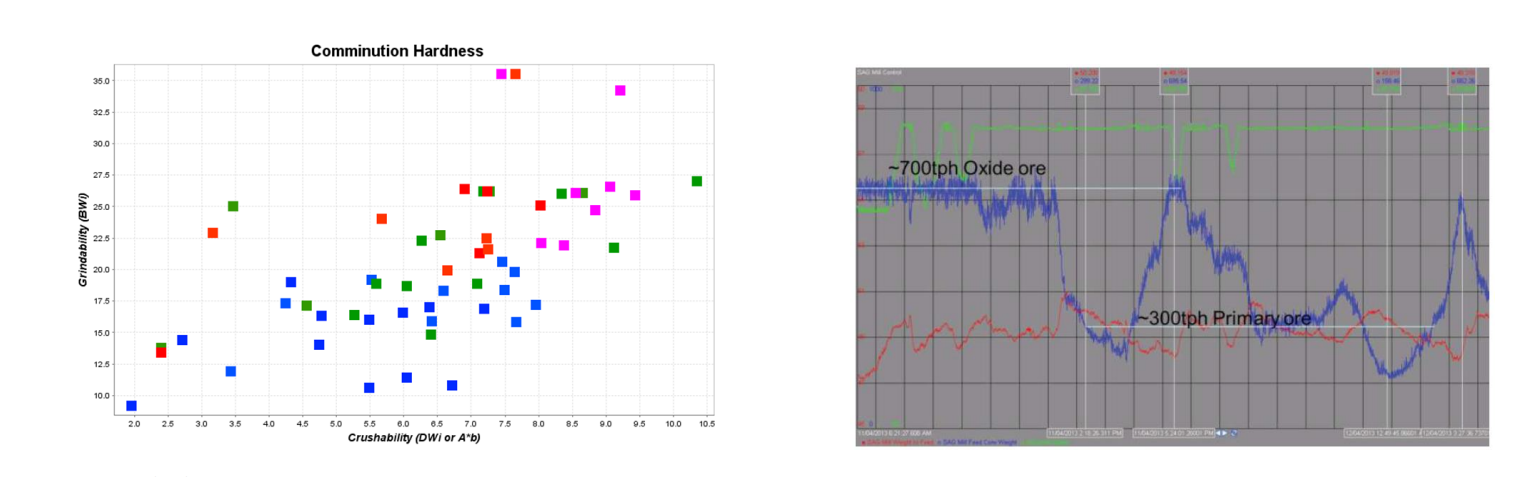

The proportion of primary ore will increase and becomes harder as shown in the LHS figure below. Hence a proactive management program was initiated to focus on maintaining and enhancing production in the future.

The feasibility design throughput of the mill processing the harder primary ore was estimated to be around 400 tph compared to 700 tph for the oxide ore. However as can be seen the RHS figure below, the mill throughput for the primary ore was often as low as 300 tph – lower than the design and hence a significant business risk. Other risks included inefficiency in milling and mining, SAG mill liner damage, higher maintenance for machinery, storage bins and conveyors.

Objectives

As part of the initiative to maintain and enhance production in the future, BHX and JKTech collaboratively undertook a program focussed on throughput based on a scaled down physical asset management approach as shown in the figure below.

The program consists of the four components with the focus on this paper in brief on the first two components:

Predict - the key process parameters and expected performance from a blasting and milling perspective for life of mine.

Control - optimisation of drill and blast to improve fragmentation and throughput for the harder primary ores while minimising dilution and ore loss.

Outcomes

Prediction

- Spatial model of estimated key process parameters including Blastability Index (BI), SAG Mill Crushability (Axb), Bond Mill work Index (Bwi)

- Spatial model of expected powder factors to achieve consistent target fragmentation

- Spatial model of estimated throughput, recovery and metal/hr

- Estimated throughput and metal production profiles on an annual basis

- Identification of deviations of estimated throughput and metal production compared to budgeted.

- Use of BI and other parameters in drill and blast optimisation.

Control

- Increase in bench height from 5 to 10m - increase in throughput of 24% over actual.

- More consistent and finer fragmentation with higher energy blasts – increase in throughput of 25-50% over assumptions in feasibility study.

- Improvement in minimising dilution and ore loss through measurement and modelling.

- Significant reduction in wall damage through use of active split.