This is a summary of the paper and presentation at The Third AusIMM International Geometallurgy Conference (GeoMet) 2016.

Role of an Ore Type

The most common view of an 'ore type' is that it is essentially a classification of ore with similar metallurgical performance. The role of an ore type is to 'enable optimum processing method(s) to be selected, the expected revenue and operation costs leading to the appropriate ore blending and mine planning' (Lewis 2013).

Hence it is commonly used to classify ore within a mineral deposit based on one or more dominant characteristics and used to facilitate communication between technical departments and units operations for decision making.

The Limitations of Standard Ore Types

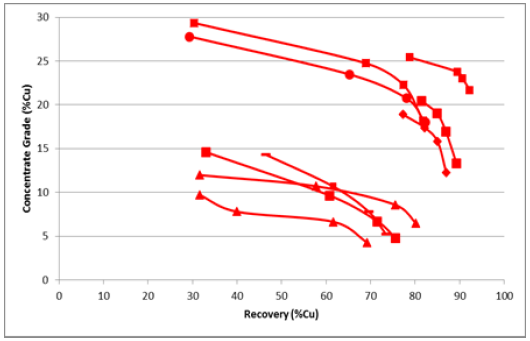

Traditionally the definition of all types have focused on recovery and have been based on classification by the geologists supported by some meta logical test work in recent decades this has been extended to highlight both physical and cost performance is associated with other components of the metallurgical value chain however the traditional geological resource or types/domains will not necessarily be appropriate for the various metallurgical process is being considered as shown for recovery in the figure below.

Traditionally the definition of all types have focused on recovery and have been based on classification by the geologists supported by some meta logical test work in recent decades this has been extended to highlight both physical and cost performance is associated with other components of the metallurgical value chain however the traditional geological resource or types/domains will not necessarily be appropriate for the various metallurgical process is being considered as shown for recovery in the figure below.

The results show two distinct groups and suggests that the application of the same treatment process to the two groups would create very different copper concentrate products and hence value.

So this all type not have consistent grade recovery performance and assigning a single value of a performance parameter be it an average or percentile would be misleading the plant rarely sees single value but rather sees a range of values over anytime.

Such performance assumptions impact many aspects of the operation across all time frames and the value chain including flowsheet design mind planning budgeting forecasting operational efficiency and reconciliation.

Extending across the value chain

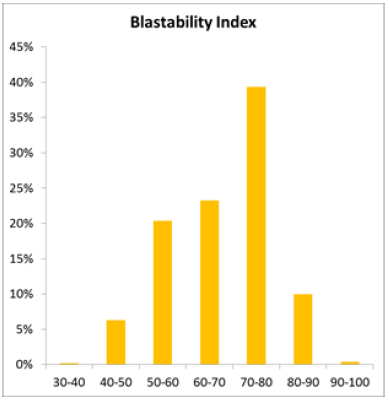

This becomes even more problematic when other processes within the value chain are considered such as blasting, loading, conveying, AMD from waste rock, de-watering, product quality etc.

This becomes even more problematic when other processes within the value chain are considered such as blasting, loading, conveying, AMD from waste rock, de-watering, product quality etc.

An example is to the right, where within a single ore type there is considerable variability in blastability (the ease at which a rock mass can be blasted).

The application of the same blast design and powder factor to this ore type results in a variability in fragmentation distribution which directly impacts on loading times and throughput.

Moving beyond or type

At the end of the day an ore type exists to assist in making decisions. Otherwise it is information for information's sake and hence an irrelevancy.

At the end of the day an ore type exists to assist in making decisions. Otherwise it is information for information's sake and hence an irrelevancy.

Probably worse is where decisions are made based on the assumption or expectation that an ore type carries relevant information but doesn't in reality.

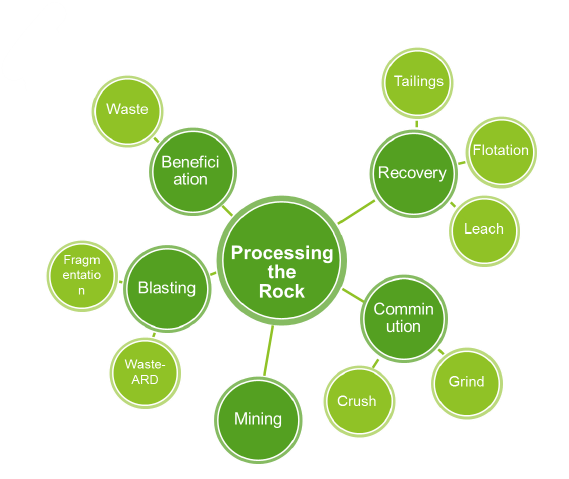

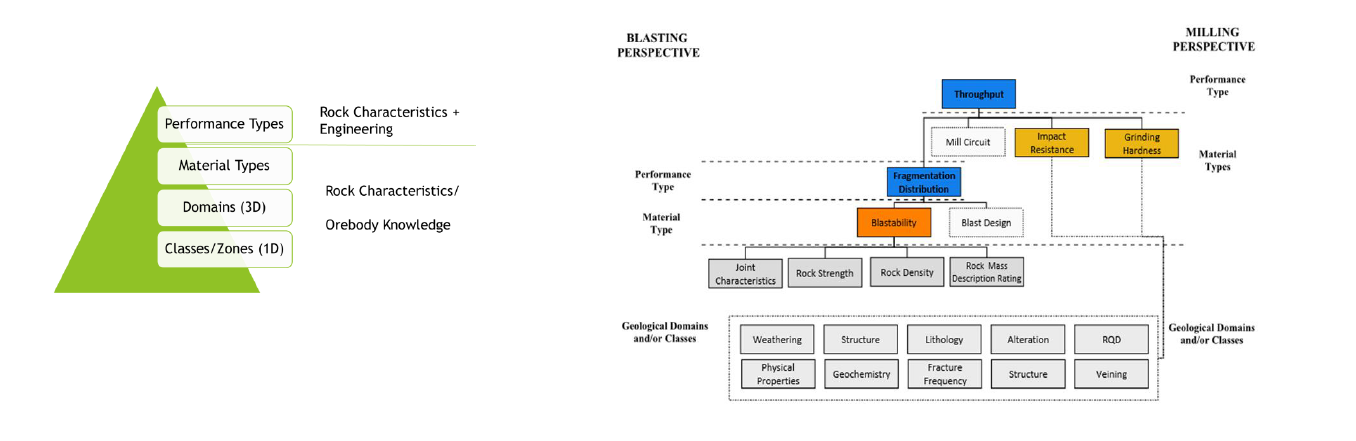

The ore type is referenced by many disciplines and functional areas and expected to provide all the information for decision making. Thus a single ore type becomes insufficient and multiple layers and 'types' of ore types are required. Here a framework is proposed to address this issue.

Two key aspects of this framework are the Material Type and the Performance Type. A Material Type reflects the intrinsic rock properties that impact on the relevant process. A Performance Type is a volume that hassimilar performance. The performance is determined by applying an engineering model to the intrinsic rock properties.

One type doesn't fit all and may be different depending on the perspective of the user. As shown below a Performance Type from a blasting perspective becomes a Material Type from a milling perspective.

Such a framework for the classification of materials within a deposit considers the receivers of information, how the embedded information will be and can be used, and the decision making requirements. It should assist in creating clarity and understanding for all those involved in the project or operations and make the classification meaningful and relevant.