While process data are important for real-time monitoring, performance analysis and operational decision-making in plant operation, they are intended primarily for immediate operational uses and lack the details and granularity that plant surveys can provide. Plant surveys provide information about the operation that otherwise cannot be obtained through automated systems or daily samples.

The need for a flotation survey arises when the circuit experiences lower-than-expected performance in recovery, struggles to meet product grade specification, or in anticipation for changes in ore type and future expansion.

Flotation surveys allow for the evaluation of down-the-bank performance including cell mass pull, froth carry rate, bank and circuit recovery, and more. This not only helps metallurgists benchmark their circuit, but also enables diagnostics and identification of potential bottlenecks and issues that may hinder process performance. A typical example is the presence of elevated penalty elements in the final concentrate, which usually affects the spot price of the commodity. If the source of the contaminant can be tracked as it progresses through the circuit, a control strategy can be implemented to enhance the product's quality.

A flotation survey is essentially a high-resolution snapshot of the flotation circuit performance at typical operating conditions. This means taking samples of slurry when the circuit is at a steady state while processing a representative or specific ore type.

When selecting a survey type, it is crucial to take into account the specific information needed. A basic block-style survey is appropriate for simple issues, while a detailed survey, done cell-by-cell is necessary for more complex problems. Having a clearly defined survey objective not only leads to favourable results but also allows for efficient use of resources and budget.

The types of flotation surveys range from simple surveys that involve sampling of flotation feed and final product streams, to more comprehensive surveys such as standard bank or full circuit surveys. If your circuit is having trouble meeting recovery and/or grade targets, despite multiple unsuccessful attempts to lift performance, then a thorough plant survey is typically necessary and may be combined with a mineralogical assessment of the selected stream to investigate the root cause and pinpoint any possible underlying problems.

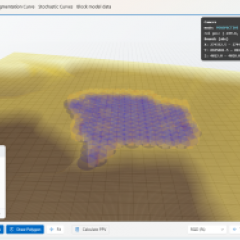

A survey campaign for the development of a flotation model requires additional data collection, such as gas dispersion measurements and hot flotation tests of selected slurry streams. In some cases, a belt-cut of the surveyed ore sample might need to be taken for further test work.

Not surprisingly, the increase in data resolution comes with greater complexity in planning, execution, and subsequently, higher costs. Choosing the right approach will not only help achieve the intended objectives but offer the most cost-effective solution.

The success or failure of a survey is dependent on management, logistics and correct sampling methodology. Considerations should be given to the following in the management and execution of a flotation campaign:

- Survey Objectives - a well-defined project objective is crucial to selecting the right survey type and enabling sufficient data collection for analysis.

- Survey Planning -

- Type and sampling time - Once the type of survey is determined, review the circuit flowsheet to determine a list of streams to be sampled, the type of sampling, sampling point locations and accessibility, as well as the amount of sample required. The stream solid density should be considered when deciding the amount of wet slurry taken at any sampling point to ensure sufficient mass collection for sizing, size-by-size assay, mineralogy, or any other required analysis, but not too excessive to hinder post-survey sample processing such as filtering and drying.

- Logistics - The logistics on the day of the survey need to be carefully planned and managed to ensure sampling is completed in a correct and timely manner. The date and duration of the survey needs to take into account ore availability, circuit stability and resource availability etc. The sourcing of sampling equipment, buckets, laboratory equipment (float cell, filter press, oven etc.) are some of the tasks that need to be considered in the planning stage. Additionally, understanding sample processing, sizing and assay requirements is helpful to allow enough laboratory resources to avoid backlog and delay. It is important to inform all relevant parties of the campaign and the significance of it, as well as avoiding a clash with routine maintenance and planned shutdowns. Effective communication is the key to ensuring everyone involved understands their roles and tasks.

- Operating condition - Once the ore type is selected the survey is then scheduled to match the target ore availability. Plant operators should be made aware of the purpose of the campaign as well as the importance of maintaining the circuit stability during the whole course of the sampling period. The circuit should be operating at either typical circuit conditions or as specified to suit the survey objective. No changes should be made during the sampling period. If, for any reason, the circuit stability is lost, it needs to be communicated to the survey manager, who may make the call to terminate sampling.

- Supplementary requirements - Requirements for other measurements such as gas dispersion, laboratory testwork, belt-cut etc. needs to be considered and planned accordingly.

- Survey data management system - the recording of information during (eg. flowrate, lip times) and after the survey (eg. wet weight, dry weight) should be carefully managed to prevent loss of information necessary for data processing at a later stage.

- Execution -

- Safety is paramount in everything we do and should never be compromised. Ensure that safety standards and procedures are practiced and adhered to.

- It is very helpful to have a practice survey to confirm survey coordination and logistics and to ensure everyone is comfortable and confident with the sampling technique and procedure.

- Correct tools and sampling techniques should be used to ensure the accuracy and representation of the samples.

- Plant conditions should be monitored for disturbances throughout the sampling period, and everyone should be prepared to terminate sampling if the circuit becomes unstable.

- Ensure relevant DCS data, such as feed throughput, assays, air rates, level etc. are captured for future processing.

JKTech offers flotation support through consulting and test work. Please contact us to learn more about our flotation capabilities.