Background

Ore control is a fundamental process in mining that involves the categorisation of materials to ensure each is directed towards its most economically beneficial use. Traditionally, mining polygons, which delineate specific areas for loading and hauling activities, are defined manually. This manual process is time-consuming and introduces variability in results due to individual discretion. Additionally, pre-blast definitions often fail to account for the distribution of material post-blast, leading to inefficiencies.

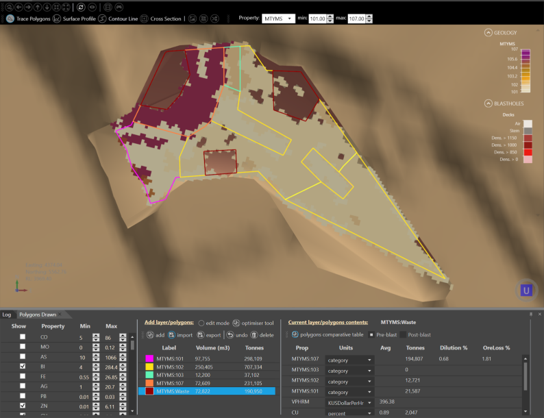

The Mining Polygons Generator Tool was developed to address these issues by automating the generation of mining polygons based on block model data and user-defined operational criteria. Integrated with the blast movement and ore control solution developed at the University of Queensland (JKVBOC), this tool leverages functionalities such as polygon editing with on-the-go reserve reportability, 3D visualisation of contents, and post-blast analysis.

This tool significantly reduces the time required to generate mining polygons while increasing the accuracy and economic impact of ore control activities. By categorising sections within a blast area and optimising polygon geometry for operational efficiency and economic output, the tool addresses the variability and inefficiencies associated with manual polygon definition. The tool's ability to consider post-blast material distribution further optimises resource allocation, enhancing economic returns.

Methodology

The development and implementation of the Mining Polygons Generator Tool followed a systematic and data-driven approach. Data from separate blasting events, including block models, topography, blast boundaries and existing polygons, were collated. The tool's functionality was then applied in two steps: automated polygon generation based on user-defined settings, followed by manual editing to refine the polygons for both practical mining conditions and content optimisation.

Results

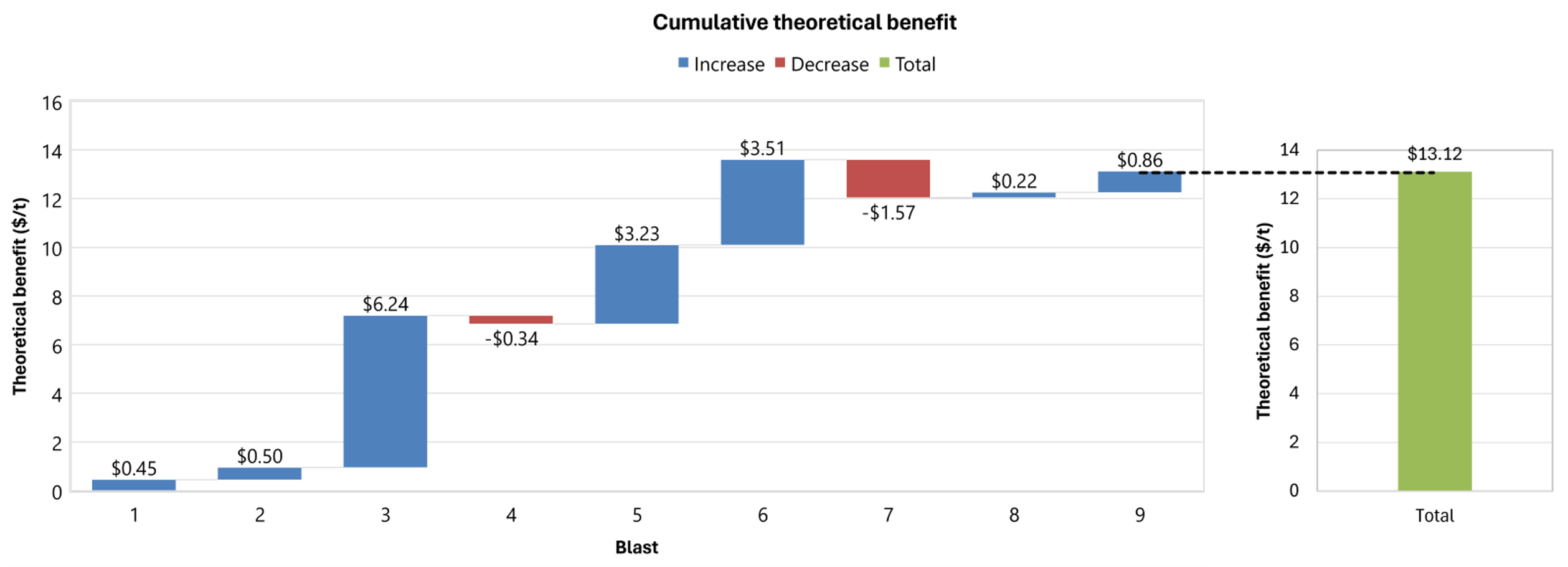

Pilot tests over nine blasts showed that the tool could generate mining polygons semi-automatically in a fraction of the time previously required, including the editing process. The results indicated a positive impact on theoretical economic value per hour and metal content across most blasts. The cumulative theoretical benefit demonstrated the tool's potential for substantial economic gains.

Future Plans

Future plans for the Mining Polygons Generator Tool include extending its functionality to further account for post-blast ore distribution. This enhancement is expected to optimise resource allocation even more effectively, increasing economic returns. Continuous refinement and testing in various mining environments will ensure the tool evolves to meet the dynamic needs of the industry.

The table below illustrates the adverse effects on the theoretical economic value per hour (VPHRM) and dilution percentage when post-blast ore distribution is disregarded. This demonstration utilised pre-blast, manually drawn polygons.

The semi-automation of mining polygon generation using the Mining Polygons Generator Tool proves to be both feasible and economically advantageous. Its integration with the JKVBOC software provides geologists with a robust solution to enhance ore control optimisation strategies. Acknowledging post-blast material distribution reveals further opportunities for refinement.

JKTech also offers drill and blast related support through software and consulting. Please contact us if you would like to learn more about our mining capabilities.