This is a technical article based on a proven tool to which a metallurgist can use to help guide future strategies and decision‐making: mineralogy. From learning how past performance could have been improved to anticipating the best processing strategies heading forward, understanding mineralogy is the first step to that elusive quick-win.

“Quick‐wins” can be elusive in mineral processing. Complex processes, noisy data, and a general need to avoid risk can overwhelm metallurgists and bog down process improvement initiatives with lingering uncertainty about where to even begin.

It should therefore be of some relief to know that there is a proven tool to which a metallurgist can use to help guide future strategies and decision‐making: mineralogy.

Mineralogy is a big driver for many of the strategies underpinning mineral processes. From the target grind size of a comminution circuit and its subsequent throughput, to reagent schemes used in flotation, to the amount of regrinding required to achieve target grades, understanding mineralogy and its implications can help define strategies and sensible processing philosophies. Yet how many of these variables are conventionally “set‐and‐ forget”, when they should most likely be tailored to the mineralogy of the current feed?

Following are some examples of recent “quick‐wins” that were made apparent by interrogating mineralogy data.

Improvement of flotation recovery through reduced lime addition

Lime is commonly added to elevate flotation pulp pH as a means of depressing non-valuable iron sulphides such as pyrite, although this will also cause some depression of valuable metal sulphides as an unwanted side‐effect. In one large copper‐gold operation, a very high cleaner circuit pH of around 11.8 was typically targeted. However, analysis of the feed mineralogy indicated very low levels of pyrite, which meant that high lime additions were not necessary. Upon reducing pH levels to 8.5, an improvement in cleaner copper recovery of 1.2% was realised due to improved flotation kinetics, without a decline in concentrate grades. Additional benefits included reduced lime consumption and cost savings, as well as reduced scaling of pipes and tanks in the concentrator.

Increasing throughput by identifying “forgiving ores”

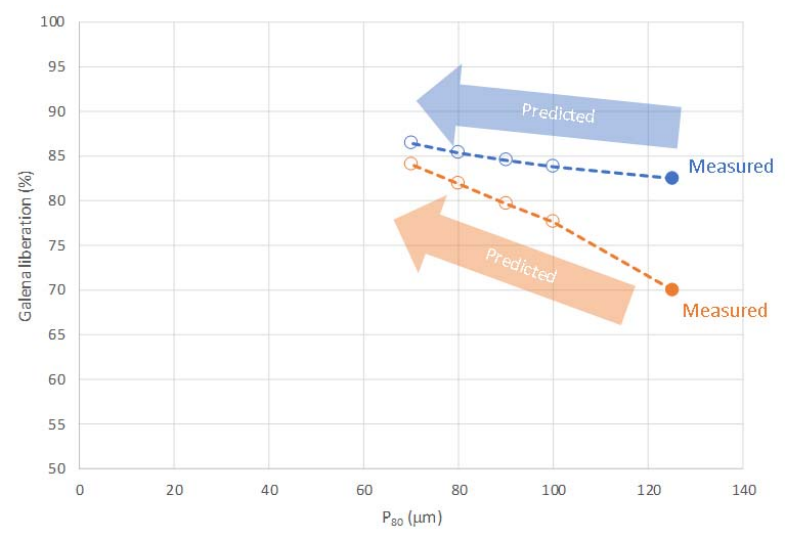

The desired grinding circuit product size is frequently a major constraint on overall throughput. However, there is often very little knowledge about how flexible this target is, and whether it is truly applicable to the diverse material‐types that are processed in a concentrator. The graph below shows how galena liberation changes with P80 for two different materials processed in a Pb/Zn flotation circuit. Each sample was analysed at a P80 of 125 mm, but liberation predictions could be made for progressively finer sizings as shown in the chart. It can be seen that finer product sizings (and correspondingly lower throughputs) are required to achieve adequate levels of liberation for the orange sample. The blue sample however, can be seen to be very “forgiving”. Finer grinds do not yield significant liberation benefits for this sample, and when processed through the circuit, an appropriate strategy would be to target higher throughputs while letting the grind size drift to coarser ranges.

The desired grinding circuit product size is frequently a major constraint on overall throughput. However, there is often very little knowledge about how flexible this target is, and whether it is truly applicable to the diverse material‐types that are processed in a concentrator. The graph below shows how galena liberation changes with P80 for two different materials processed in a Pb/Zn flotation circuit. Each sample was analysed at a P80 of 125 mm, but liberation predictions could be made for progressively finer sizings as shown in the chart. It can be seen that finer product sizings (and correspondingly lower throughputs) are required to achieve adequate levels of liberation for the orange sample. The blue sample however, can be seen to be very “forgiving”. Finer grinds do not yield significant liberation benefits for this sample, and when processed through the circuit, an appropriate strategy would be to target higher throughputs while letting the grind size drift to coarser ranges.

Diagnosing poor cleaner performance

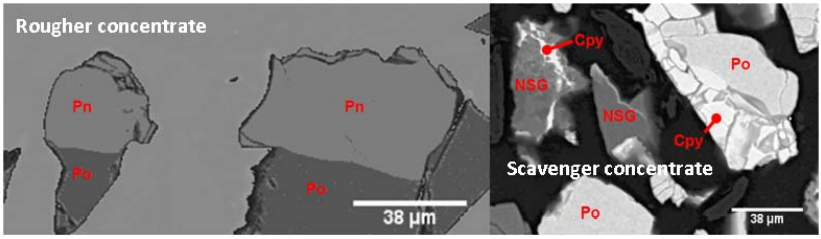

At a nickel‐copper flotation concentrator, the metal‐upgrade across the cleaner flotation circuit was poor. Preliminary improvement efforts were focussed around the reagent scheme and pulp densities in the cleaner cells, to no avail. It was not until the mineralogy of the rougher circuit concentrates was analysed, that insight into the root cause of the issue was obtained. While the first two rougher concentrates were of sufficient liberation for good cleaning performance, the scavenger concentrate liberation was constraining the cleaners (no regrind mill was present in the circuit). It can be seen from the photomicrographs that, compared to the rougher concentrate, the scavenger concentrate had more complex intergrowths between chalcopyrite and non‐sulphide gangue, and between pentlandite and pyrrhotite. A regrind P80 of between 15‐20 mm was identified as appropriate for the scavenger concentrate, which was targeted in the next phase of testing.

Conclusions

Understanding mineralogy, and variability in mineralogy, is key to tailoring processing strategies to suit material types that are fed into a concentrator. Root‐causes of problems can be diagnosed, constraints can be alleviated, and previously unseen opportunities can suddenly become apparent. Properly interpreted from a processing angle, mineralogy should be the first step to that elusive “quick‐win”.

For further information about this topic, contact Dr Tim Vizcarra at t.vizcarra@jktech.com.au.