Introduction

Despite major advances in the drill and blast field over the past 15 years, many drill & blast (D&B) designs still rely on rules of thumb and “cookie-cutter” layouts replicated across domains of similarity. Skill shortages and staff rotations further limit sustained optimisation, leaving downstream benefits on the table. A Drill and Blast Expert System (ES) addresses this gap by embedding objective, evidence-based design into day-to-day practice and linking D&B to Mine-to-Mill targets. This ES is being developed by Associate Professor Ítalo Onederra of the School of Mechanical and Mining Engineering, The University of Queensland, with JKTech supporting its deployment as a web application to facilitate operational adoption and integration via API interoperability.

Why an ES now

Industry surveys show a clear shift towards process/decision intelligence and integrated remote operating centres. In D&B, that means moving from guideline-based design to systems that quantify objectives (fragmentation, damage, vibration, airblast, dilution, etc.), assemble the right models, and compare alternatives before execution. The blast engineering design process, from objectives and domain definition through implementation to performance reconciliation, is depicted in the Figure 1, and is the backbone the ES uses.

What the Expert System does

The ES integrates multi-resolution geotechnical and geometallurgical data with equipment/product constraints to generate and recommend fit-for-purpose designs across short, medium and long-term horizons (“blasting to meet customer specifications” such as comminution equipment or excavators). It enables multi-scenario simulations, rapid forecasting, and routine adoption of Mine-to-Mill strategies.

System architecture in 3 steps

1. Input layer:

A simple step by step upload and selection process of - Mine planning parameters, design objectives/targets (e.g. P80), drilling equipment specifications, explosive specifications.

2. Computational layer:

- A validated breakage model estimates borehole expansion/pressure attenuation to predict fracture contribution to fragmentation (based on Esen–Onederra and subsequent improvements).

- Deterministic and stochastic fragmentation frameworks incorporate QA/QC variables; spatial rock mass variability is passed explicitly via

- bench-scale block models.

- Empirical checks verify practical constraints (e.g., burden vs diameter, scaled depth of burial, width-over-tracks).

- Performance reconciliation and auto-calibration close the loop.

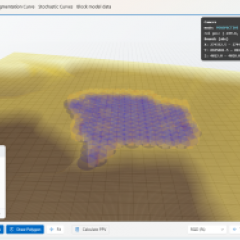

3. Output layer:

2D/3D visuals, KPIs (fragmentation curves, powder factor, costs), and reports exportable to Excel/Power BI (Figure 2).

Value delivered

- Elevated D&B know-how: Semi-automated parameter selection that complements site experience.

- Data-driven decisions: Routine forecasting and reconciliation support for continuous improvement and Mine-to-Mill alignment.

- Operational agility: Simple and fast response to changing rock characteristics across planning horizons.

Conclusion

An Expert System for D&B transforms design from guideline-driven to objective, rock domain-aware, and continuously reconciled practice. The approach demonstrated here shows that realistic, implementable designs and their downstream consequences can be forecast in advance, avoiding one-size-fits-all patterns and sustaining Mine-to-Mill outcomes.

References

Onederra, I, "Advancing Drill & Blast Design and Decision Support for Sustainable Mine Process Optimisation Strategies" Fragblast 2025, Keynote.

Please contact us to learn more about how JKTech can support your drill & blast and Mine-to-Mill activities through our consulting, professional development and software services.