Introduction

The first point in the AMIRA P754 Code of Practice highlights the importance of a Check-in Check-out (CICO) system. This requires that all streams entering and exiting the process for which the balance is being performed are measured for flow and sampled for analysis. However, it is uncommon for plants to comply with this requirement, particularly for tailing streams. For the measurements that do occur, there is always some degree of error dependent on the quality of the measurement.

For plants that use ‘n-product’ calculations for primary accounting, the only mass flow rate measurement used when calculating ‘balanced’ values is from the mill feed weightometer. Therefore, maintaining accuracy of feed mass flow rate measurement is of the utmost importance as it has a significant influence in the calculated product mass flow rate.

Weightometer Accuracy and Installation

The Code states a minimum installed precision for weighers used for primary accounting. They must have a maximum permissible error rating of OIML (Organisation Internationale de Métrologie Légale) Class 0.5. This is a ±0.5% in-service precision, as per OIML R-50 (or equivalent local standard).

To achieve a high level of accuracy, the weightometer must be installed in a suitable location (as per manufacturer guidelines). Basic installation considerations include:

- Distance from the feed point

- Consistent belt tension

- Correctly aligned idlers in the belt scale area

- Protection from wind

To maintain a high level of accuracy, quality calibrations should be carried out routinely, including after any work on the weighframe, belt scale, or belt.

Case Study: Diagnosing Bias in Concentrate Reporting

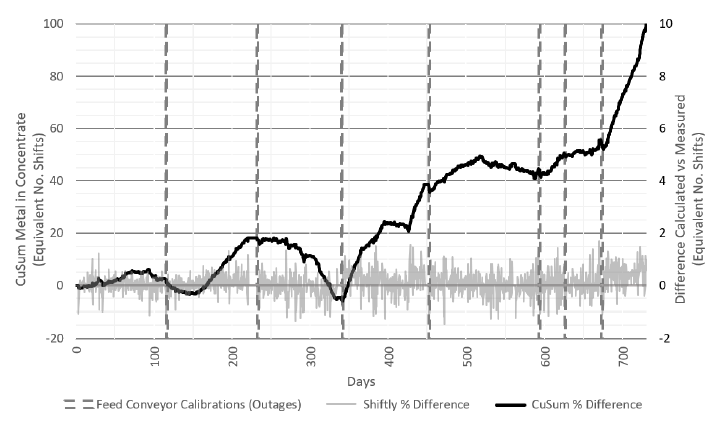

In a previous JKTech study, an operation observed a consistent positive adjustment (or ‘write-up’) for tonnes of concentrate during end-of-month (EOM) reconciliation over a 12-month period. The root cause was unknown.

An audit was undertaken of the key metallurgical accounting files, and the circuit and on-site laboratory were physically inspected. Focus areas included the overall strategy of reconciliation procedures and the source and direction of bias in measurements that could contribute to the production write-ups.

The ‘mass balance’ method used on this site required feed tonnage, feed assays, concentrate assays, and final tail assays to calculate shiftly and daily concentrate tonnages. Potential sources of bias included the feed weightometer, feed/product samplers, and laboratory sample preparation and assay procedures. Additional reconciliation inputs included the concentrate weighbridge and stockpile survey.

Following the site visit, it was determined that the samplers, laboratory procedures, concentrate weighbridge, and stockpile surveys were unlikely to be the sources of the observed bias. This left the feed weightometer as the remaining suspect instrument, which otherwise had no obvious issues upon visual inspection.

Maintenance logbooks indicated that the weightometer typically underwent calibration during scheduled maintenance shutdowns using static weights. This method, though common, is undesirable as it does not correct for anything that alters the transfer of belt load through the weighing platform to the load cells. This is particularly concerning after adjustments to the weighing platform or belt replacements, both of which had occurred multiple times in the previous year.

This technical bulletin is based on a paper "Bean Counting, How Hard Can It Be? – Common Mistakes in Metallurgical Accounting", presented at the AusIMM Mill Operators Conference.

JKTech provides metallurgical accounting support through audits, consulting, and training. Please contact us to learn more about how we can help improve your production reporting and reconciliation.